Our steam turbine field services engineers perform hundreds of minor and major maintenance and repairs across Europe, Asia and Africa.

Efficiency in planning and execution

Arabelle Solutions can perform a comprehensive range of overhaul and field repair services across a wide range of turbines.

Maintenance network

With an extensive network and mobile workshops in a variety of strategic regions, we can provide quick and effective engineering maintenance services across Europe, Asia and Africa. These services include manufacturing and specialist repair of any steam turbine part, from individual buckets to a new rotor.

Arabelle Solutions also provides a full range of outage planning, management, and execution activities. Unplanned work is significantly reduced, thanks to our extensive fleet-management experience.

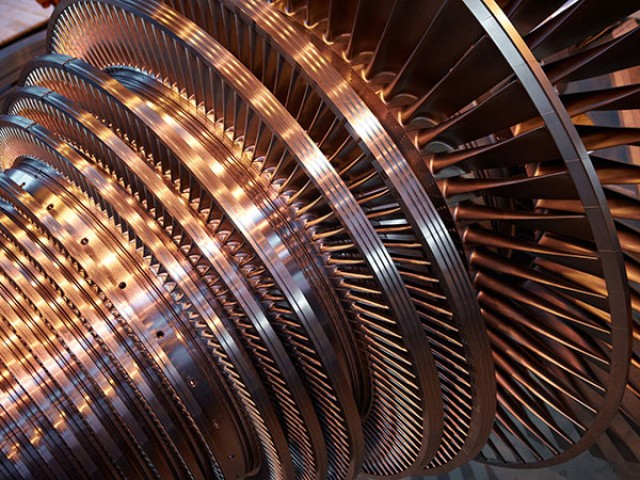

Rotor, blading, and casing repairs

To save cost and lead times associated with replacement parts, we offer a range of complex repair techniques for steam turbines. Many of these relate to weld repairs.

Rotor repair: With more than 80 years of welded rotor technology experience, we provide joining of new forged sections, shaft buttering, disc repair, and disc head buildup with new material. We also offer several techniques for straightening rotors.

Blading repair: With experience across the range of blading, we provide dressing and weld repairs for all types of fixed and moving blades, including linking and attachment features. For last stage blades (LSBs), we also offer leading edge hardening and shielding options.

Casing repair: We can correct minor cracking and change the geometry of highly stressed areas of steam turbines. We can also re-round distorted casings and add new weld material.