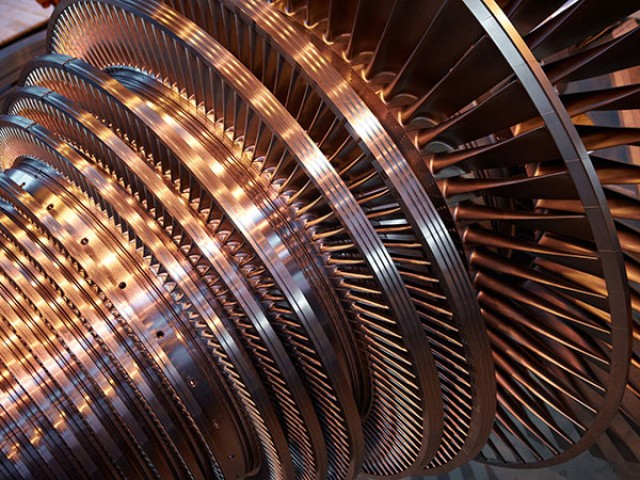

Our field experts have the technical knowledge, experience and equipment to service nuclear steam turbines across Europe, Asia and Africa.

Expert services at your site

We bring the inspection and repairs directly to your location, and help to reduce outage time and achieve substantial cost savings. Our onsite inspection and repair teams offer comprehensive field services, extensive tooling, experience and efficient responsiveness — from inspections, repair, and machining to highly specialized services.

- Extensive tooling: The team is ready to tackle your needs with an extensive portable equipment and an tooling inventory.

- Experience: Our team of highly qualified specialists includes machining supervisors, engineers and technicians.

- Responsiveness: Our equipment is completely mobile and can be transported to any required destination across Europe, Asia and Africa.

Inspections and analysis

Our steam turbine inspection and safety assessment services help prevent catastrophic high-speed-rotor issues.

- Boresonic inspection services: Inspection of older bored rotors looks for indications of deterioration from the inside to the outside.

- Periphery ultrasonic testing services: Ultrasonic testing for solid rotors examines the outside of the rotor for indications of potential issues.

- Phased array wheel dovetail testing services: Phased array testing looks for indications of stress corrosion cracking (SCC) in time to repair the wheel and prevent bucket liberation.

- Wheelsonic inspection services: Wheelsonic Inspections employ a series of tests to evaluate the integrity of wheels on a built-up, low-pressure rotor.

Explore our services portfolio

Pioneering steam turbines

From the world’s most powerful steam turbine in operation to modular designs optimized for SMRs, our turbines are suitable for any reactor type from 50 MW to 1900 MW.